The Micro Support Axis Pro micromanipulator is a bench-top microsampling system for failure analysis and particle isolation. The system includes a zoom microscope, a motorized XYZ stage, and two motorized arms. The arms can be configured with a wide range of tools for sampling of materials smaller than 10 μm. Motion of the sample stage and arms are performed through a PC interface with simple mouse control. The system is perfect for particle and defect isolation with a benchtop micromanipulator.

This system allows the user to easily remove material with a wide range of tools that are too difficult that are too difficult to use by hand.

Micro Support Axis Pro Micromanipulator

Some of the common tools and techniques used for failure analysis and particle isolation include:

Tungsten probe

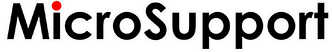

Tungsten probes are often used to isolate particles by a specialized microscopist. Particles typically adhere to the probes through an electrostatic interaction.

Particle isolation by hand has gotten more difficult as the size of critical defects/particles has gotten smaller. The precise positional control of the Micro Support Axis Pro micromanipulator facilitates this type of operation on smaller defects.

Particle isolation using tungsten probes

Use of two tungsten probes to hold a defect

The Axis Pro micromanipulator can also hold a particle between two probes and move the two arms simultaneously. This facilitates extracting a difficult particle from a matrix, especially in situations where grains and particles do not exhibit electrostatic adhesion to a single probe.

Microtweezer Tool Set

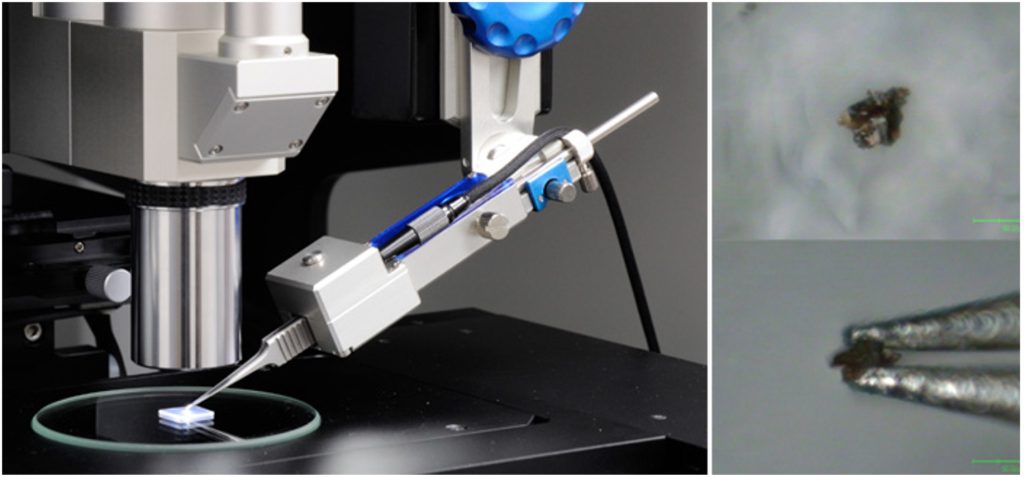

Microtweezers are valuable for isolated larger defects or when the defect is embedded in an adhesive material. The operator moves the microtweezers into place and closes them around the defect using a manual or motorized mechanism mounted onto the tool holder.

Microtweezers holder and close-up of particle in micro-tweezers

Vacuum absorption accessory

A micropipette with a small applied vacuum can also hold a particle for isolation. The operator positions a micropipette near than the defect and then applies a small vacuum to the micropipette to hold the particle. After moving the particle to the desired deposition location, the vacuum is turned off and the particle can be released.

Movement of particles using microtweezers and the vacuum adsorption tool

Tungsten carbide tool to scrape material off surface

A horizontal tungsten carbide tool can scrape material off a surface in situations where a defect is located below the surface. The operator closely monitors the material until the defect has been exposed.

Tungsten Carbide Tool

Milling Pro accessory for smooth removal of surface

The horizontal tungsten carbide scraping tool can also be mounted onto the Milling Pro accessory that induced an ultrasonic vibration in the tip to provide a smoother scraping of material.

Milling Pro

Video showing the operation of the Milling Pro accessory

Conclusions

The Micro Support Axis Pro micromanipulator is a powerful system for defect isolation and microsampling.

In addition to the techniques described here, there are many other tools that the system can accommodate for specific tasks, and the system is open access which allows users to implement new tools as needed.