Description and Features

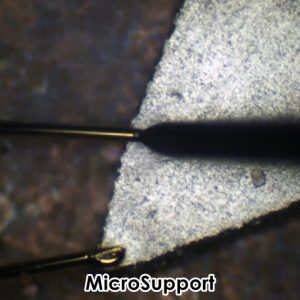

- Micro-spot welding system was developed for small wiring like 30μm wire.

- Constant resistance value display enables reliable sample setting.

- Resistance and current values are displayed to check the connection status after welding.

- Output voltage and pulse generation time can be easily set at the touch of a button.

- Clean welding with less dust and spatter can be achieved.

- The welding time can be set short to minimize thermal effects.

- High-capacity capacitor storing energy for pulse current delivery

- Maximize precision positioning by combining it with a manipulator for optimal results.

Video

Specifications

| Control method | Digital control by microcomputer |

| Output voltage | 1.0V to 20.0V (can be set in 0.05 increments) |

| Power source | AC 100 V (50 Hz/60 Hz) |

| Output current | Maximum ~200A |

| Welding time | 0.01mS~0.99mS (Set in units of 0.01 mS) |

| Dimensions | W150×H280×D271(mm) |

| Weight | Approx. 3.5 kg |

Standard Package

| MW-2 | Mainbody, AC power cable, foot switch and connecting cable,output terminal connecting plugs (2 pieces) |

Recommended Manipulators

| Model | Code | Type |

| QuickPro | QP-3RH | Electric Standard Type |

| AxisPro | APSS-301 | Fully Integrated Electric Type |