Description

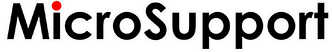

- MillingPro MIL-1 cuts foreign objects embedded in materials like resin, a task which was too difficult.

- When attached to our micromanipulators (APFC/ APSS), MillingPro enables cutting objects buried at depth of 2-300 µm with real-time visual monitoring

- The MillingPro kit includes dedicated cutting tools with various cutting area and depth controls.

- MillingPro is an adjustable/flexible cutting tool that can be used for a wide range of materials, including resin, glass, silicon wafers, ferrous and non-ferrous metals, and rocks.

Video

Applications

Depth cutting: surface removal

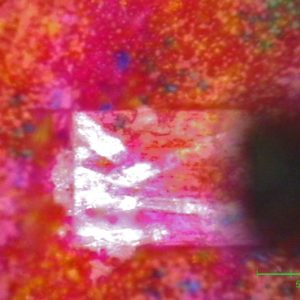

- Micro IR (microscopic IR) and thinning of foreign particles embedded in resin material

- Flat cutting of embedded foreign substances (preparation for ATR measurements)

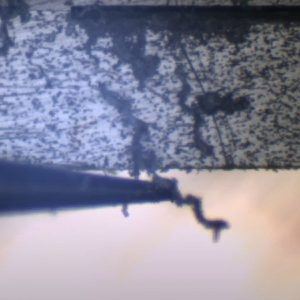

- Micron-level step cutting of thin film on resin surface

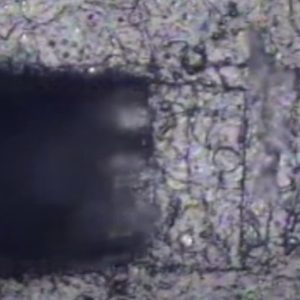

- Flat cutting of a wide range of surfaces at a fixed depth (from 50µm square)

- Marking on glass, wafer, and metal samples (for FIB processing)

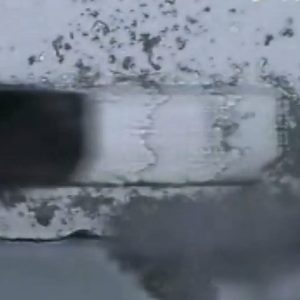

- Pinpoint cutting of IC packages and LCD panel encapsulation materials

- Contact with internal defect (sample pretreatment for X-ray microscopy or ruler drawing on an IC chip)

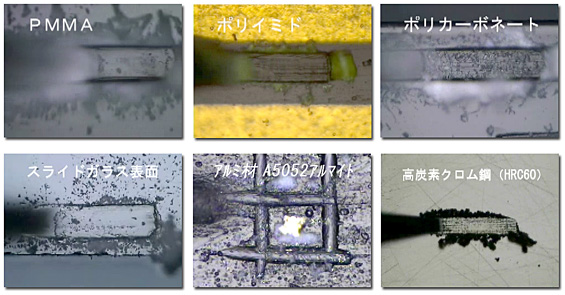

PMMA, Polyimide, Polycarbonate,

Surface of slide glass, Aluminum A5052 Anodized, High-carbon chromium steel

Specifications

| Controller unit | 85(W)×290(D)×140(H)mm, 3kg |

| Milling unit | φ28×140(L)mm, 0.2kg |

| Power supply | AC100~230V 50/60Hz |

| Rated power consumption | 25VA |

Standard Package

MillingPro

| MIL-1 | Use for our manipulator |

Special tools

| Micro Peelers | MPE-1M | tungsten carbide, tip size 50μm |

| Micro Peelers | MPE-2M | tungsten carbide, tip size 100μm |

| Tungsten carbide Probes | CP-M | Needle, tip diameter 10μm |

| Tungsten Probes | TP-M | Needle, tip diameter 0.5μm |

| Milling tools set | MILT-SET | Four above-mentioned kinds of tools were combined. |